Fashion socks

Custom Low cut Fashion Socks Wholesale Low cut fashion socks are the most popular socks in summer, adopt anti-skid and anti-drop technology, selected ice silk, lace, glass silk fabrics, comfortable and refreshing, cool feet. Many customers of BFL socks factory have customized in large quantities, Therefore, it has become a very important product for us. We have signed contract rates with more than 45 wholesalers. Through these relationships, we can provide you with a wealth of production experience for your customized BFL Low cut fashoin socks. With BFL as partners, customized BFL Low cut ladies socks will be much easier, you will only need to send designs, and we will do the rest. BFL aims to be your best OEM socks manufacturer from China. Ask for a better quote now.

Request A Free Quote

Your Professional & Reliable Children Socks Manufacturer and Wholesale Supplier

If you are looking for a professional Baby socks manufacturer in China, BFL Socks Factory can be your premier partner. BFL can always provide you the best quality and rates.

Ask for a quick quote and let us take care of your next shipment of Chil dren socks.

Request a Free Quote

Product Information

✔ 80% cotton,16.5% polyester,3.5% spandex

Machine Wash

✔ Anti-slip design:No show socks for women anti-slip silicone grippers,arch compression work together to ensure these women's socks stay in place.

✔ Cushioned & padded buffer:Socks for women with padded sole,made with compact siro spun yarn, provide lasting buffer during exercises.

✔ Breathable and absorbent:Mesh design with absorbent combed cotton improves ventilation keeping feet dry and cool

✔ Lasting Comfort:80% combed cotton,elastic cuff with padded heel area,ankle socks women offer enhanced wearing comfort and durability.

✔ All round Fun-Color Socks-Of unique sorbet colors,no show socks made for daily exercise be it running,hiking,golf or yoga.Go well with sneakers,vans…also excellent causal house socks to be worn indoors without shoes!

✔ Everyday made better: we listen to customer feedback and fine-tune every detail to ensure quality, fit, and comfort, any problem please contact us, we only want to give you a best service!

How socks are manufactured

Have you ever wondered how to make socks on an industrial level? Unfortunately, the days when most socks were made entirely by hand are long gone. A large-scale, more industrialized manufacturing process is required to produce enough socks to meet demand—the UK alone purchased approximately 120 million pairs of socks last year. This is a complex process involving knitting, stitching, forming, pairing and continuous quality inspection. Although many of these stages still rely on the workforce, some aspects have now been automated. This is good news for knitters, who can continue to knit for fun and know our socks needs are being met.

Knitting: Before starting the sock knitting process, the raw materials are washed and spun into yarn. Coloured socks are either dyed after knitting or knitted with previously dyed yarn, called grain yarn. Through the use of grained yarns, many attractive colour blends and combinations can be achieved.

The knitting machine has a cylinder with 84 to 200 knitting needles around it. The yarn is fed into the knitting machine and knitted around the cylinder. The sock is incorporated with the toes open, and all parts of the socks come out like a finished tube.

Seam/Seam Process: The most significant advantage of the knitting machine is minimizing seams. The fewer seams the socks have, the less friction and the more comfortable they are.

After the socks are knitted, the seams between the toes must be closed. Once the socks leave the knitting machine, a quality check is performed, and then the hose enters the stitching area where the toe opening is sewn. Our silk and bamboo socks series are connected by hand to provide maximum comfort.

Product Pictures

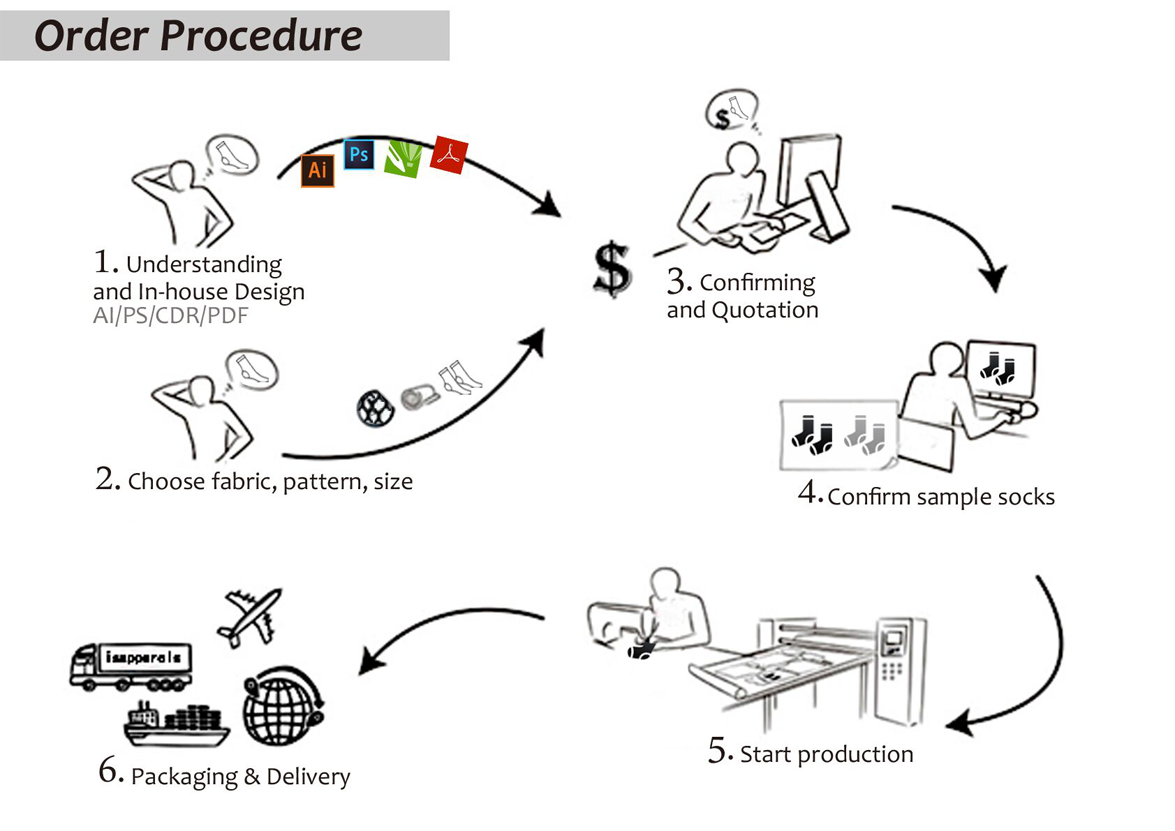

Trade Flow Chart

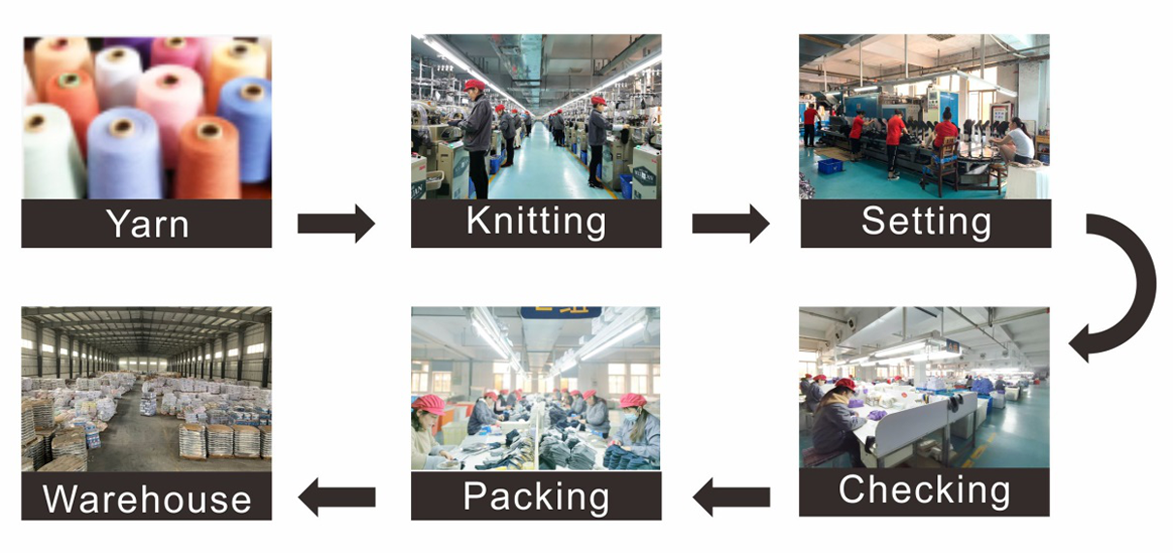

Production Flow Chart

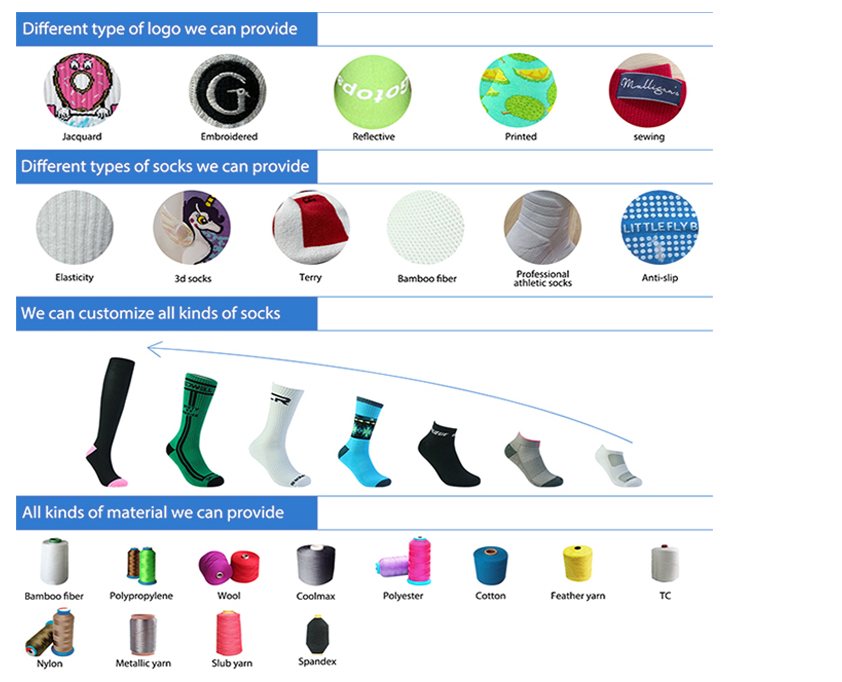

Our Services

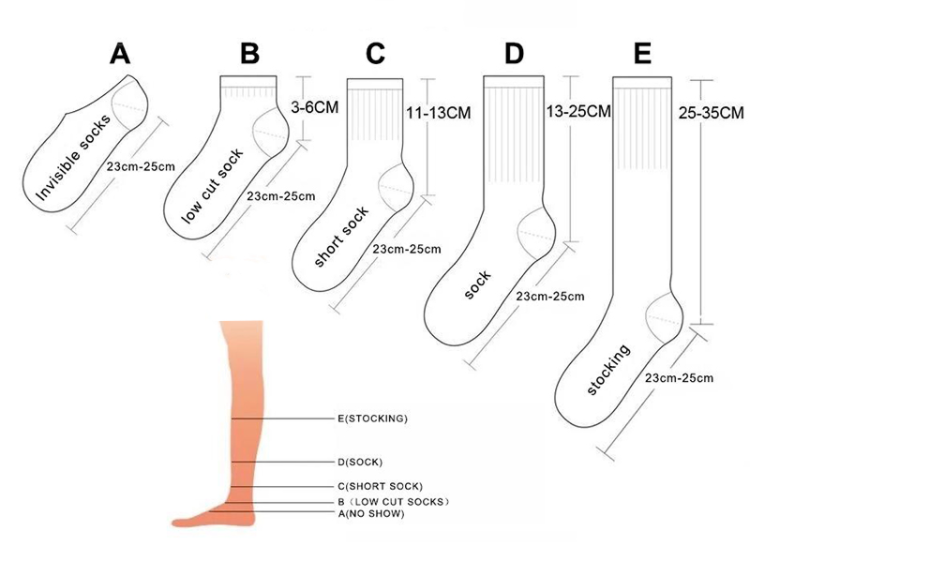

Custom Socks Size

Packing And Delivery