Custom Wholesale Best Sublimation Printing Socks

Custom Wholesale Best Sublimation Printing Socks BFL socks factory is very familiar with manufacturing Sublimation Socks, we are producing over 2.5 million pairs Printing Socks for customers in the world since 1999. Being the biggest custom sock manufacturers in China, you can count on us for the best quality and reasonable prices.

Request A Free Quote

Your Professional & Reliable Children Socks Manufacturer and Wholesale Supplier

If you are looking for a professional Baby socks manufacturer in China, BFL Socks Factory can be your premier partner. BFL can always provide you the best quality and rates.

Ask for a quick quote and let us take care of your next shipment of Chil dren socks.

Request a Free Quote

Product Information

✔80% Cotton, 17% Polyester, 3% Spandex

✔Machine Wash

✔Size information: the sock dye sublimation jig is approx. 7.83 x 3.35 inches, durable and steady to use, not easy to rust or break; Blank white sublimation socks are approx. 15.7 x 3.35 inches, nice elasticity makes them fit most teenagers and adults, classic and simple design is suitable for both women and men

✔Comfortable to wear: this heat press jig works nicely with these blank printable athletic socks, which will not warp, crack or wear easily; Our sublimation tube socks are soft and comfortable to touch and wear, elastic and breathable, durable and easy to wash without deforming, which ensures your snug wearing all day, can serve you for a long time

✔Enjoy DIY fun: these practical sublimation socks are white and blank, providing you with plenty of creative space, you can choose your favorite picture or text printing; This metal dye sublimation jig can stretch socks, ensuring that the pattern you want to print will cover the sock, allowing the socks to be filled with your own personality and style

✔Meaningful gifts choice: printable white sports socks are the ideal choice for you to make innovative and personalized socks; You can give them to your friends, family, team members, classmates and others on occasions such as birthdays, graduation, events, anniversaries, etc., to express your care and greetings, these interesting and practical sublimation socks will win their favor

✔Everyday made better: we listen to customer feedback and fine-tune every detail to ensure quality, fit, and comfort, any problem please contact us, we only want to give you a best service!

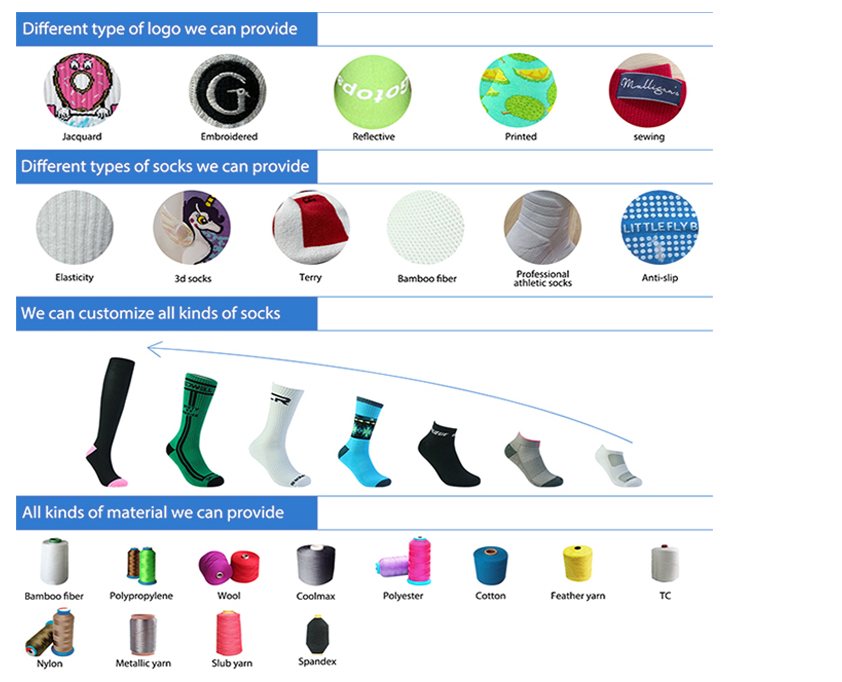

Different printing techniques

1. Jacquard fabrication: While the word “Jacquard” might give this technique the illusion of difficulty or sophistication, it’s the most basic and oldest method of sock decoration on this list. It doesn’t even involve any printing at all. Instead, different coloured threads are woven together to create the desired pattern, making for beautiful results when dealing with more straightforward or classic designs. Jacquard is likely to be responsible for the socks you’re wearing right now. However, if you plan to incorporate complex pictures or designs beyond a simple geometric pattern into your personalised stockings, Jacquard might not be the best option for you.

2. Dye sublimation: A more modern technique of sock printing is called dye sublimation, which utilises the chemical process of sublimation to impart designs directly onto the sock material. Sublimation refers to the transition of a solid directly into a vapour, bypassing the liquid stage altogether. When creating socks, the concrete is the link, placed onto a piece of transfer paper in solid form before being transferred onto the desired fabric at a high temperature and pressure. This helps to create far more intricate patterns than are capable with traditional weaving techniques and eliminates the possibility that the design might crack or erode over time – a fundamental attribute for an article of clothing that undergoes as much wear and tear as a pair of socks. Best suited to synthetic fabrics, dye sublimation is unsuitable for cotton or natural-blend socks.

3. 360-degree printing: 360-degree printing is very similar to dye sublimation in that it is appropriate only for synthetic materials and uses sublimation to achieve incredibly detailed results. The difference lies in the exact process of transferring the ink to the sock itself. As the name suggests, 360-degree printing uses a wraparound technique of sock creation by stretching the material around a cylinder or the mould of a human foot, allowing the printer to impart the chosen image, design or pattern onto the sock with minimal visibility of the seams. In this sense, 360-degree printing is probably the most advanced method of personalised sock printing, given that it allows for intricate detail with the minimum of seam visibility. If those things are important to you, it might be the best choice on the table.

Product Pictures

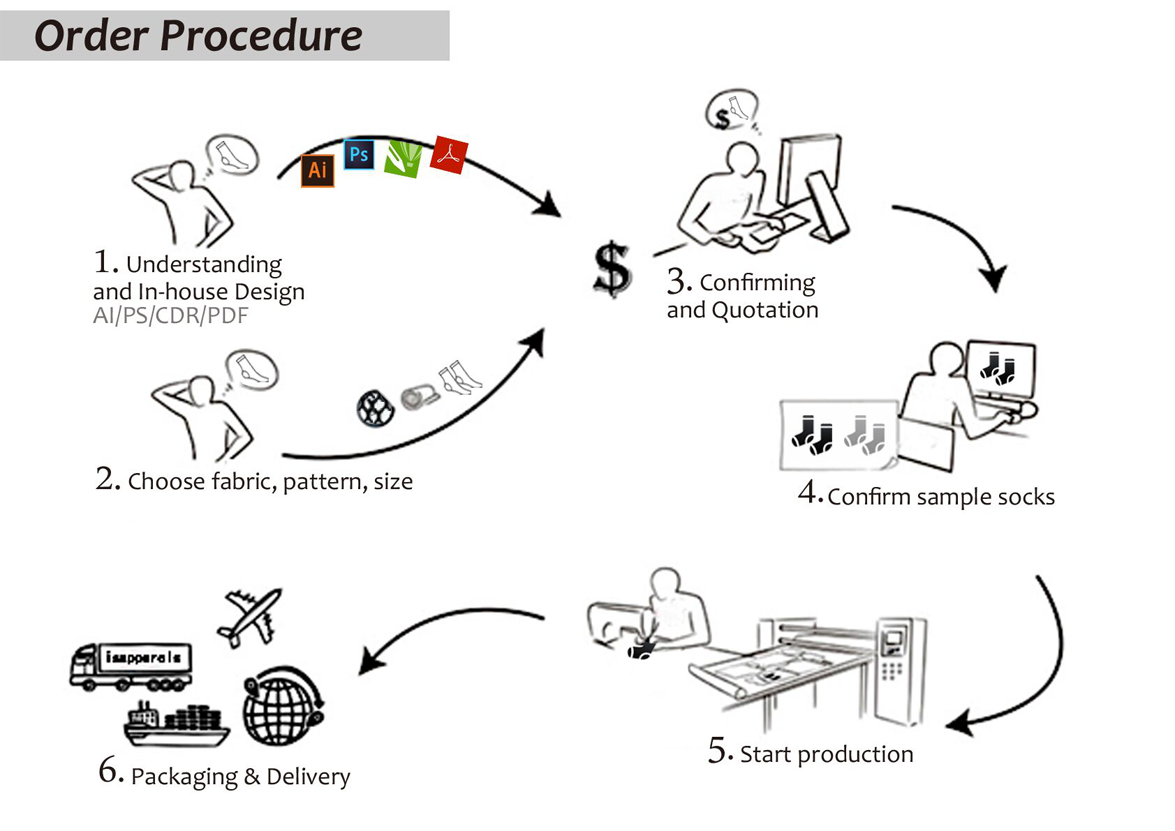

Trade Flow Chart

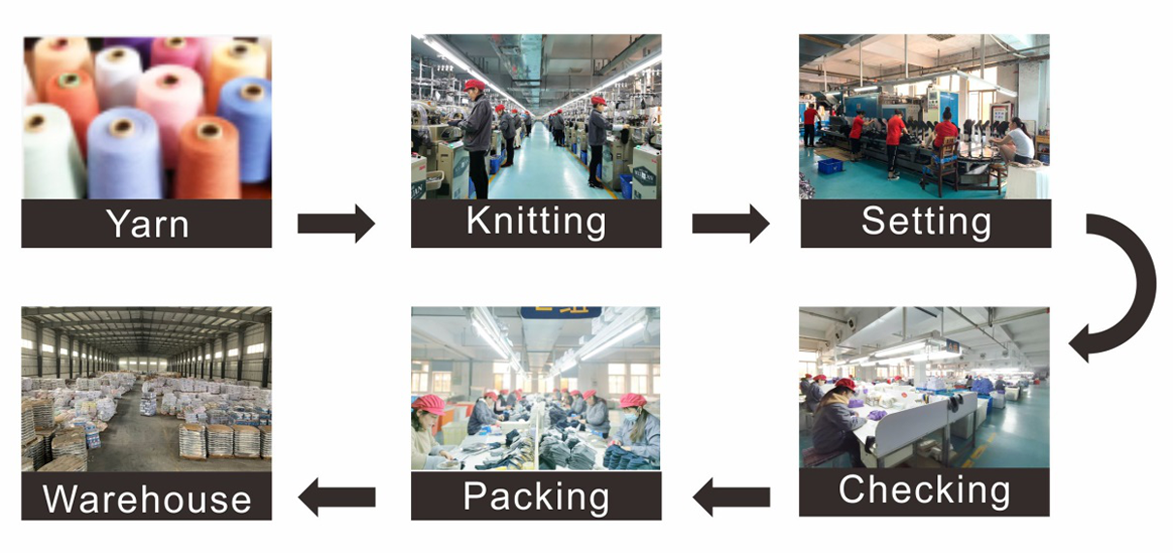

Production Flow Chart

Our Services

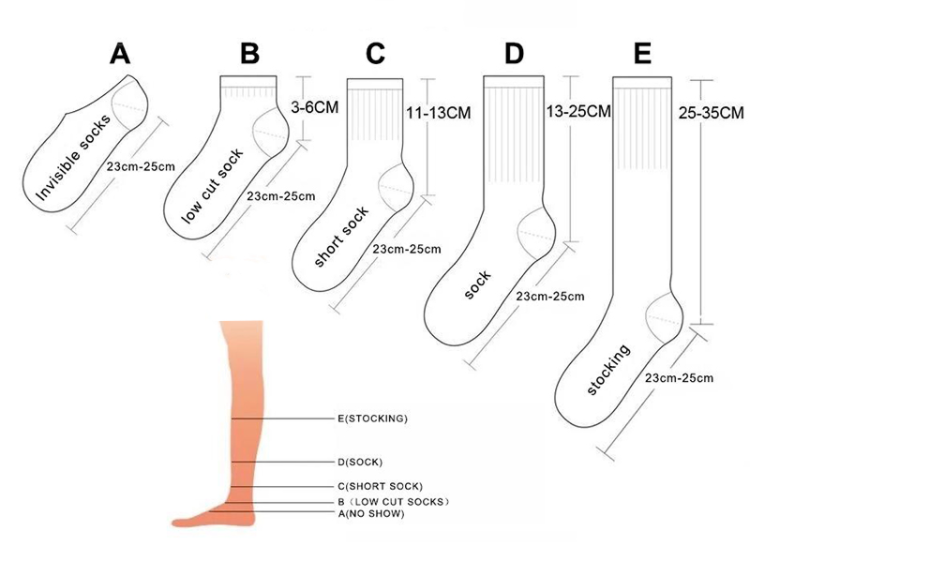

Custom Socks Size

Packing And Delivery